The Colleague Program

The Colleague Program represented Statoil’s first systematic investment in behaviour-based safety (BBS) and was introduced as a response to increasing concern about offshore safety. Throughout the 1990s, various efficiency measures had weakened safety, and both trade unions and the Petroleum Directorate voiced strong criticism of the safety culture in the oil industry. Statoil and the management at the Gullfaks field were particularly singled out after several serious incidents.

The poem “I Could Have Saved a Life” was a key element in Statoil’s new safety initiative in 2002 and summarized the core message: safety is a personal responsibility.

I could have saved a life that day,

But I chose to look the other way.

It wasn’t that I didn’t care;

I had the time, and I was there.

Now every time I see his wife,

I know I should have saved his life.

That guilt is something I must bear;

But it isn’t something you need share.

(Excerpt from “I Could Have Saved a Life”)

Something Had to Be Done

In 2002, Statoil’s management decided to implement measures to improve safety. Despite a decline in minor incidents, the number of near-misses with serious potential had not decreased. The solution was the Colleague Program – an initiative to enhance safety through behavioural and cultural change, with the goal of achieving an injury-free workplace. The program aimed to help employees make the right decisions and act in ways that promote safety.[REMOVE]Fotnote: Stople, Marianne. Nullfilosofi i praksis. Et case av Statoil Mongstad. Masteroppgave Institutt for administrasjon og organisasjonsvitenskap. Universitetet i Bergen. 2007S: 12.

Around the year 2000, BBS had made its way into the Norwegian oil industry, with roots going back to the 1930s. The philosophy is based on the idea that accidents are not random but have causes – and can therefore be prevented.[REMOVE]Fotnote: St.meld. nr 7 (2001–2002). Om helse, miljø og sikkerhet i petroleumsvirksomheten. As early as 1996, Statoil had introduced the concept of the “zero mindset,” which became the foundation for the company’s goal of zero accidents and injuries. The Colleague Program can be seen as a direct continuation of this focus.[REMOVE]

Fotnote: Stople, Marianne. Nullfilosofi i praksis. Et case av Statoil Mongstad. Masteroppgave Institutt for administrasjon og organisasjonsvitenskap. Universitetet i Bergen. 2007S: 8.

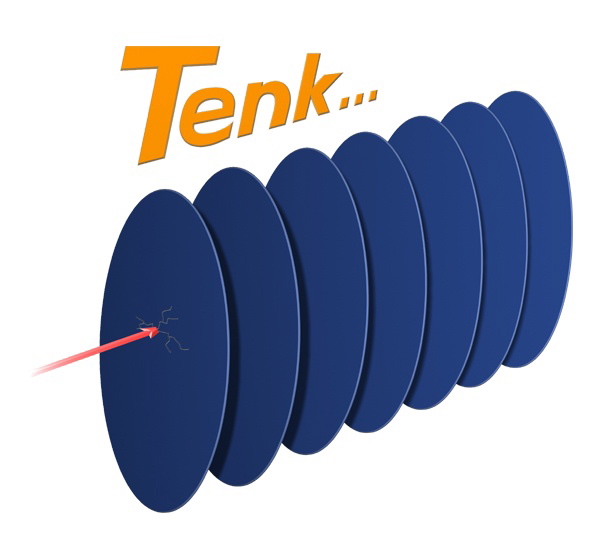

The Iceberg

A central element of the program was the iceberg analogy, drawn from DuPont’s safety system and based on H.W. Heinrich’s theories. According to the model, 88 percent of all accidents are caused by human error or behaviour. The analogy illustrates that most hazardous events occur “below the surface,” and that visible accidents are just the tip of the iceberg. Statoil embraced this thinking and set a goal to increase reporting of near-misses and unsafe conditions in order to implement preventive measures and reduce the risk of serious incidents.[REMOVE]Fotnote: Stople, Marianne. Nullfilosofi i praksis. Et case av Statoil Mongstad. Masteroppgave Institutt for administrasjon og organisasjonsvitenskap. Universitetet i Bergen. 2007S: 63.

The program emphasized barriers—both technical and “soft” barriers, such as human and organizational factors. It was built on five core principles:

- Correct Prioritization – Safety must always come first, even when it conflicts with production or cost.

- Compliance – Employees must follow applicable requirements, procedures, and guidelines.

- Open Dialogue – It should be safe and natural to raise safety concerns with leaders and colleagues.

- Ongoing Risk Assessment – Everyone must assess risk before performing a task.

- Care for One Another – Employees should dare to intervene if they see colleagues putting themselves or others at risk.

Hazardous conditions were to be identified, and risky behaviour changed. This required motivational measures and positive feedback to reinforce desired behaviour. Leadership was crucial – leaders had to show ownership, take responsibility, and be good role models. Trust between employees and management was a key factor for success.

The program was to include the entire organization, including suppliers, and be long-term. It involved a two-day gathering for all employees, where powerful real-life stories were shared. The sessions focused on a few but important messages, storytelling, involvement, and shared understanding – without finger-pointing. Follow-up lasted four years, with meetings, discussions, and initiatives to strengthen barriers, integrated into town halls, HSE meetings, and on-site activities.

At the same time, the Colleague Program and BBS were criticized for being based on an instrumental view of humans, where individuals are seen as mechanisms that can be controlled through stimuli. This could lead to a narrow focus on the individual and overlook important social and organizational factors. At the HSE conference in Stavanger in December 2002, Sigvart Zachariassen from the Petroleum Safety Authority warned against the one-sided attention BBS was receiving.[REMOVE]Fotnote: Energi24. Schjølberg, Torstein. 12. mars 2006. Kritiske søkelys på Statoils HMS-ledelse – Energi24.no He emphasized that HSE is about much more than individual behaviour – it includes leadership, staffing, training, procedures, organization, and planning.

Critics also pointed out that BBS can ignore structural conditions and the work environment, thereby overlooking root causes of accidents. Additionally, questions were raised about whether BBS undermined the tripartite cooperation – a cornerstone of Norwegian labour relations—by placing responsibility on the individual employee, contrary to the Working Environment Act’s principles of employer responsibility.

The internal control system, developed in the 1980s, gives companies the responsibility to design robust technological systems with barriers that can withstand human error. The Working Environment Act does not absolve employees of responsibility but emphasizes that technology and the workplace must be adapted to humans—not the other way around.

The Colleague Program can therefore be described as a hybrid approach. Between August 2003 and the winter of 2005, over 20,000 employees and suppliers participated in the two-day course. The main message was Safety is everyone’s responsibility. This emphasized personal accountability but was also part of a broader strategy to strengthen the safety culture. The program ended in 2007, but many of its elements continue to live on in Statoil’s HSE work.