Ten Kilometers Later: The Story of Gulltopp

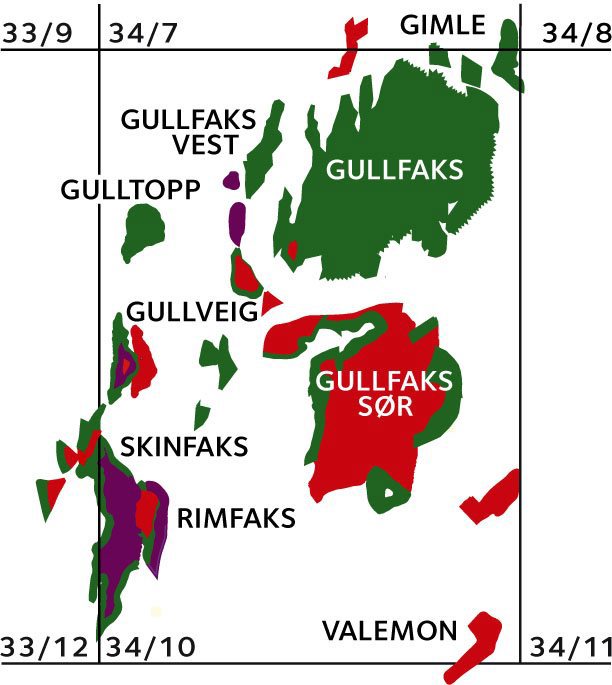

Gullfaks began production in 1986, reaching peak output in the late 1990s. The next step was to tap into oil from surrounding satellite fields. On the western edge of block 34/10, geologists identified a promising area. Initially named Dolly, the field was later renamed Gulltopp. In 2002, the rig Deepsea Trym drilled a well confirming a 115-meter oil column—large enough to be commercially viable. This was also Statoil’s first exploratory well with a U-shaped trajectory.[REMOVE]Fotnote: Jørgen Sirum et al. “Gulltopp – long well on GFA.” Technical report. TPG4851 Experts in Team, Gullfaks Village, 2008. A U-shaped well exceeds a 90-degree angle.[REMOVE]

Fotnote: NDLA. Well Trajectories. Brønnbaner – Boring – BETA – NDLA.

In the early planning phase, Statoil considered two development strategies. One option was to install a subsea template with two wells – a safer but more expensive solution requiring subsea construction, rig rental, drilling, completion, and tie-in to a production unit.[REMOVE]Fotnote: Jørgen Sirum; Magnus Helge Eriksson; Terje Hals; Bente Øygarden; Henrik Gade. ”Gulltopp lang brønn på GFA”. .” Technical report. TPG4851 Experts in Team, Gullfaks Village, 2008. Letestrategi (ntnu.no).

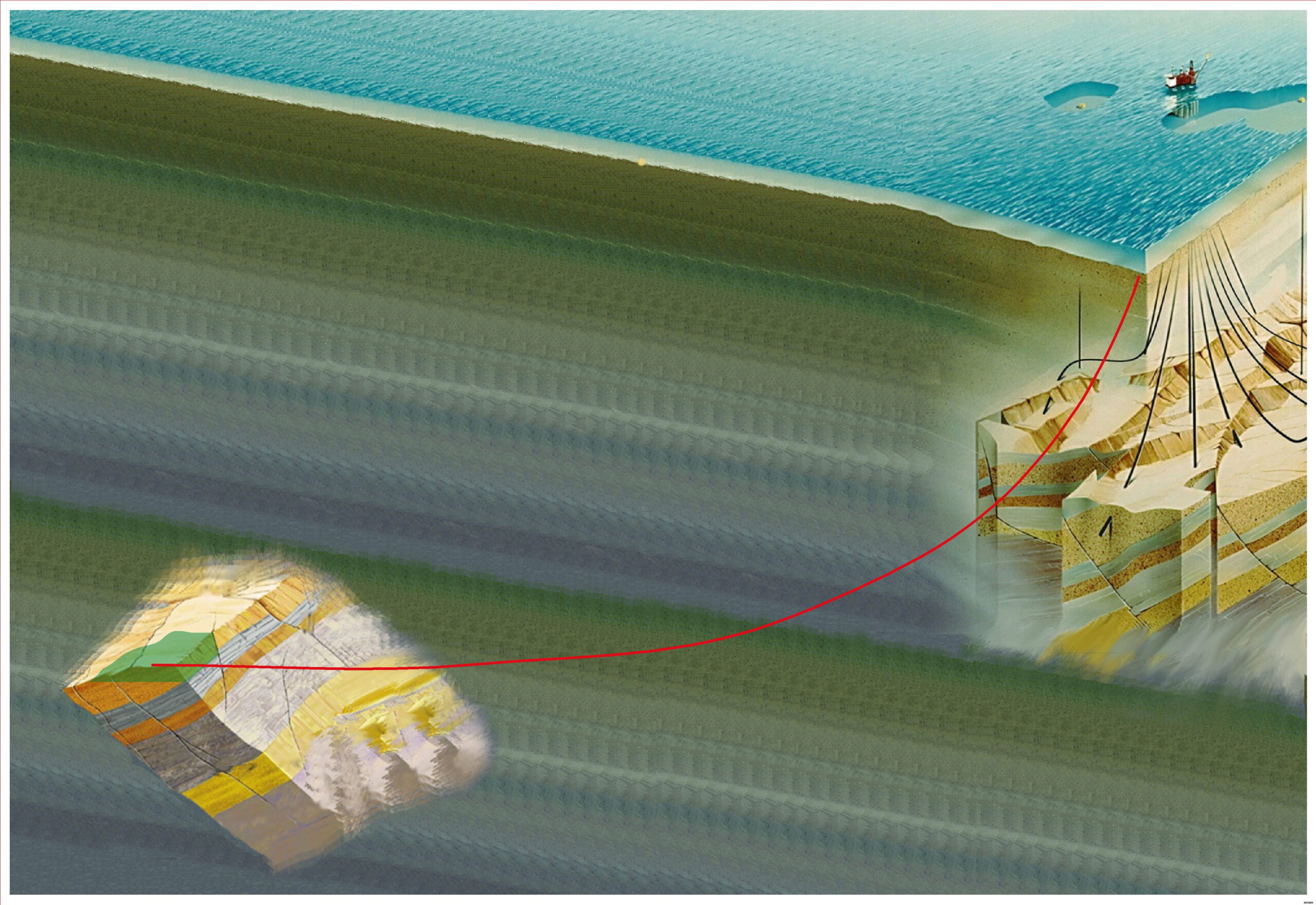

The alternative was to drill a long well from the Gullfaks A platform. At the time, such extended-reach wells were rare, and the risk of failure was higher. Still, this approach was chosen. If successful, it would be significantly more cost-effective. The well could be tied directly to the platform like any other on the field—and crucially, it could be maintained using the platform’s existing drilling equipment.[REMOVE]Fotnote: Steensen, Anders J. (2006. 2. mai). Gulltopp – flaks for Gullfaks. Teknisk Ukeblad.

However, drilling such a long well came with major challenges. Gullfaks A was only designed for wells up to six kilometers. Additional technical and material issues meant the drilling process would take time. Originally scheduled to start production in July 2005, the well didn’t come online until April 2008.

It Never Stopped Being Difficult

The well began as a sidetrack 1,100 meters down an old well on Gullfaks A. Nearly ten kilometers long, it was drilled almost entirely horizontally.

Geological conditions were especially difficult, with varying rock types and pressure levels. The oil lay unusually shallow. For every meter drilled downward, four meters had to be drilled horizontally – most of the vertical depth was achieved early in the well. The challenge was getting the drill string to advance, as it relies on gravity for forward motion.

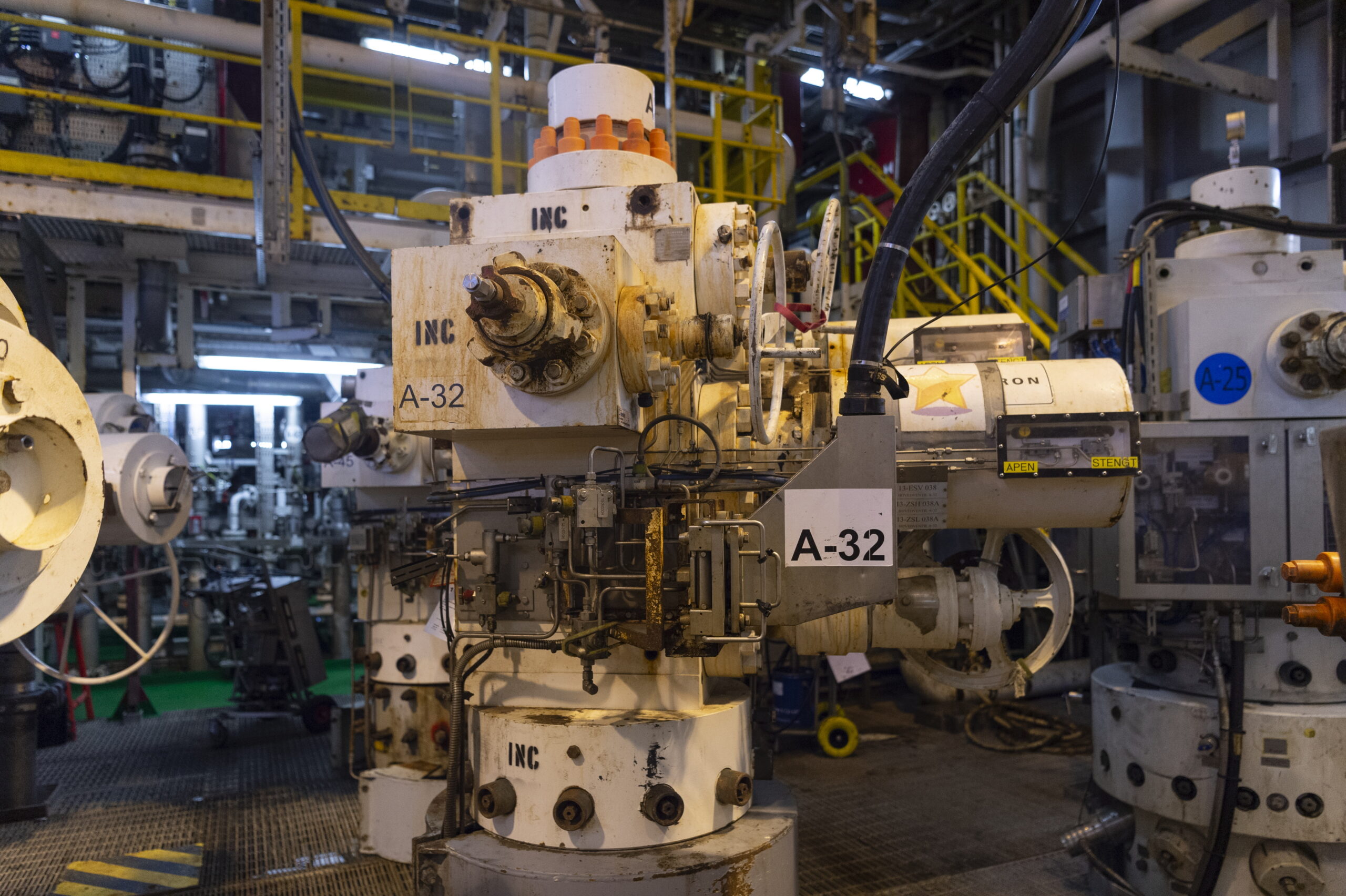

From the outset, the crew struggled with an aging rig. The drilling module on Gullfaks A dated back to the mid-1980s and was designed for wells no longer than six kilometers.[REMOVE]Fotnote: Sirum et al

In autumn 2005, with the drill bit at around 8,000 meters, the crew encountered problems. The drilling mud failed to stabilize the formation, causing the well walls to collapse and block the borehole. Attempts to clean the well failed, and the section had to be plugged. A new sidetrack was initiated from 3,200 meters.[REMOVE]Fotnote: Sintef.no Ny æra for Gullfaks. sintef.no/globalassets/upload/teknologi_og_samfunn/smartere-sammen/statoil-aktuelt.pdf/

By July 2007, with the well nearing 9,500 meters, the drill string snapped. The hole had to be plugged and abandoned again. At the same time, the rig’s braking system failed, bolts in the derrick loosened, and several steel beams cracked. One of the platform’s transformers also failed, requiring equipment upgrades and delaying operations by five months.[REMOVE]Fotnote: WE – internmagasin for StatoilHydro. (2008. mai). Brønnen som ikke ville ta slutt.

Several failed attempts followed. The final 500 meters took nearly a year to complete. But on their very last attempt, the drilling team succeeded.

On Tuesday, 8 April 2008, celebrations erupted on the Gullfaks A platform. The most complex well in StatoilHydro’s history was complete, and hydrocarbons flowed from a depth of 9,910 meters. It became the world’s longest producing well from an offshore platform. Gulltopp, along with other nearby prospects, would help secure continued operations at Gullfaks—and the experience gained would prove valuable for future projects.[REMOVE]

Fotnote: Sirum et al.

When a Russian Naval Drill Isolated GullfaksUncontrolled Gas on Gullfaks C