Removing Gullfaks’ Concrete Substructures

The three options considered for the Gullfaks concrete substructures are full

removal, partial removal, or leaving them in place.[REMOVE]Fotnote: The question of leaving concrete substructures in place is addressed in a separate article. A more detailed analysis of full removal — including transport, dismantling, recycling, as well as equipment and facilities — can be found in: AF Decom Offshore (2011). “Utredning om tekniske

utfordringer knyttet til transport, mottak og disponering av

betonginnretninger ved land – OD prosjektnummer 105801 AFDO

prosjektnummer 6001.116.”

https://www.sodir.no/globalassets/1-sodir/publikasjoner/rapporter/

af-decom-offshore-as-disponering-av-betonginnretninger.pdf This article addresses the first two.

When assessing the feasibility and method for any potential removal, it is

important to consider how the structures were once transported and installed.

Steel installations are typically transported and installed using heavy‑lift

crane vessels and/or barges. What sets concrete substructures apart is the

large inherent buoyancy of their hollow concrete cells and shafts. That was a

major advantage during tow‑out to the field: only towing power was needed to

move the structures from the fjords to their locations on the continental

shelf—even though most concrete structures were far heavier than steel ones.

Complete removal of the concrete substructure

Given the way the Gullfaks platforms’ substructures were originally towed to

the field, an obvious scenario is to try to refloat the substructure. Several

factors make this challenging. A key unknown is how firmly the parts that

penetrate, in some cases, many tens of meters into the seabed (the skirts) are

held in place. Accurately estimating the skirts’ pull‑out resistance is

critical to success. In addition comes, among other things, how aging may have

affected the structures’ capacity to withstand the loads imposed by a refloat.[REMOVE]Fotnote: Meling, John; Hausmann Rikke Ellingsen og Faulds, Eric (2018). Markedsrapport knyttet til avslutning og disponering/Avslutning og disponering av utrangerte innretninger, project no. 12635-01, document no. 12635-01-OO-R-001 (Dr.techn. Olav Olsen AS.) (The report was written on commission for the then Norwegian Petroleum Directorate, now the Norwegian Offshore Directorate.) https://kudos.dfo.no/documents/12201/files/12330.pdf

Also published at: https://www.sodir.no/aktuelt/publikasjoner/rapporter/eldre-rapporter/markedsrapport-knyttet-til-avslutning-og-disponering2/8-beskrivelse-fjerning-av-bunnfaste-plattformunderstell/ (8.1.1) Only a handful of refloat projects for concrete installations have been carried

out in northern European waters. None have taken place on the Norwegian

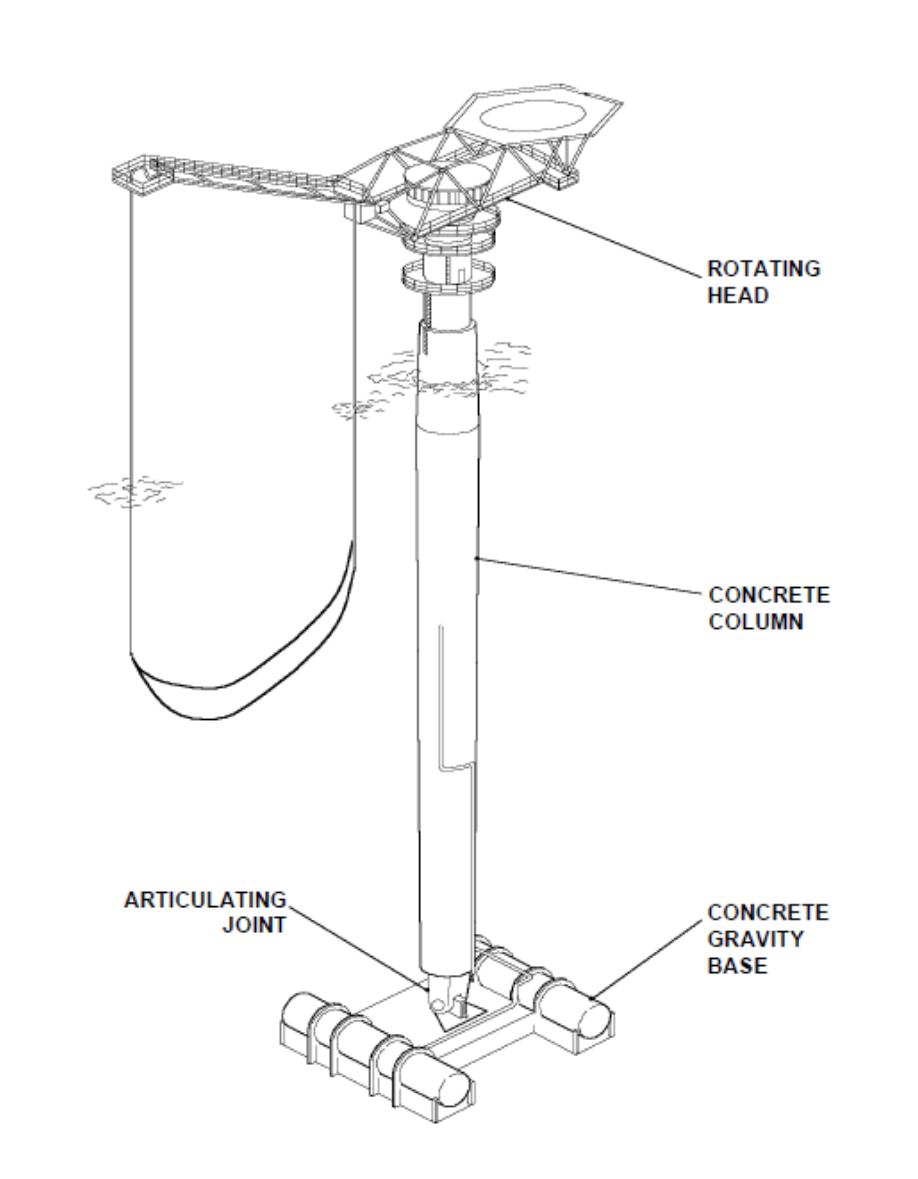

Continental Shelf (NCS). Among the very few removed by this method is the

loading column with a concrete foundation at the Maureen field on the UK

Continental Shelf (UKCS). The operation included pumping out the water that

had been used to keep the installation stable on the seabed. The concrete

structure consisted of a square base with a column 89 meters tall and between

6.5 and 9 meters in diameter.

The refloat operation was successful; the installation was towed to Stord and today serves as a breakwater for a marina there.

It is worth noting that the loading column at Maureen and other installations

that have been refloated (such as Schwedeneck A and Schwedeneck B on the

German shelf) are significantly smaller than many of the remaining concrete

installations on the NCS. In a class of its own stands the Gullfaks C

substructure at 1.5 million tonnes and 262 meters tall.[REMOVE]Fotnote: Gullfaks C had a total height of 380 metres including the deck. Gullfaks A and Gullfaks B had total heights of 270 and 220 metres respectively.

It remains to be seen whether the limited refloat experience can be extrapolated across the full range of sizes and weights of concrete substructures on the NCS in general, and for the Gullfaks platforms in particular.

Partial removal

Partial removal of a concrete platform substructure may look like a pragmatic

middle ground when full removal or leaving the structure in place seems

difficult. But this option also presents significant challenges. The main

objective in a partial removal is usually to cut away the upper sections of

the shafts so that shipping can pass unhindered above the installation. The

international standard calls for removal down to 55 meters below the lowest

tide level.

Cutting reinforced concrete under water is no simple task, not least because

it depends on extended periods of calm weather. Weather exposure complicates

stability calculations for the cut section as the work progresses.[REMOVE]Fotnote: Meling, John; Hausmann Rikke Ellingsen og Faulds, Eric (2018). Markedsrapport knyttet til avslutning og disponering/Avslutning og disponering av utrangerte innretninger, project no. 12635-01, document no. 12635-01-OO-R-001 (Dr.techn. Olav Olsen AS.) (The report was written on commission for the then Norwegian Petroleum Directorate, now the Norwegian Offshore Directorate.) https://kudos.dfo.no/documents/12201/files/12330.pdf (s. 58.)

Also published at: https://www.sodir.no/aktuelt/publikasjoner/rapporter/eldre-rapporter/markedsrapport-knyttet-til-avslutning-og-disponering2/8-beskrivelse-fjerning-av-bunnfaste-plattformunderstell/(8.1.3)

There are no known examples of this kind of partial removal, as the overall risk has

been judged to outweigh the benefits.[REMOVE]Fotnote: Meling, John; Hausmann Rikke Ellingsen og Faulds, Eric (2018). Markedsrapport knyttet til avslutning og disponering/Avslutning og disponering av utrangerte innretninger, project no. 12635-01, document no. 12635-01-OO-R-001 (Dr.techn. Olav Olsen AS.) (The report was written on commission for the then Norwegian Petroleum Directorate, now the Norwegian Offshore Directorate.) https://kudos.dfo.no/documents/12201/files/12330.pdf (s. 71.)

Also published at: https://www.sodir.no/aktuelt/publikasjoner/rapporter/eldre-rapporter/markedsrapport-knyttet-til-avslutning-og-disponering2/8-beskrivelse-fjerning-av-bunnfaste-plattformunderstell/ (8.2.3)

————-

Taken together, this suggests that, for the Gullfaks platforms, the choice in

most cases will be between removing the entire concrete substructure or

leaving it in place.