Gullfaks B slipform halted

At the end of August 1985, the dry dock in Hinnavågen was flooded with seawater. This marked the completion of the first phase of construction, and the concrete foundation for Gullfaks B was ready for flotation.

It took 50 hours to fill the dry dock. However, the concrete cells did not initially achieve the buoyancy needed to tow the structure to Gandsfjorden. To solve this, additional air was pumped under the concrete, which finally did the trick.

Nearly a month after the dry dock was flooded, the Gullfaks B foundation was anchored in Gandsfjorden, where it would remain until spring 1987. The main slipform process—casting the concrete cells from the base section to the top of the cell walls—was scheduled to begin on October 7 and was expected to take one month.[REMOVE]Fotnote: Status: internavis for Statoil-ansatte. 1985 Nr. 9 s. 14 However, that did not go as planned.

Disputes Over Wage Cuts

Norwegian Contractors (NC) was experiencing an extremely busy period during the construction of the Gullfaks B substructure. The project was being built in parallel with the outfitting of the shafts for Oseberg A. In addition, NC had secured a contract for the construction of Gullfaks C earlier that year, further increasing the pressure on ongoing projects. The company described 1985 as the busiest year in its history. [REMOVE]Fotnote: NC (1985, 5. november) 14 års suksess. Stavanger Aftenblad, s. 7

The demand for labor was high, and finding enough workers was a challenge. To speed up production by 10 percent, NC proposed increasing the workload.

In response, the Rosenberg Club, part of the Norwegian Union of General Workers (Norsk Arbeidsmannsforbund), demanded wage compensation for the increased work pressure. The piecework rate (expected production per hour) for building concrete substructures was renegotiated each time NC started work on a new Condeep platform. For Gullfaks B, the proposed rate was set 16 percent lower than for Gullfaks A. This meant workers had to produce more to earn the same hourly wage.

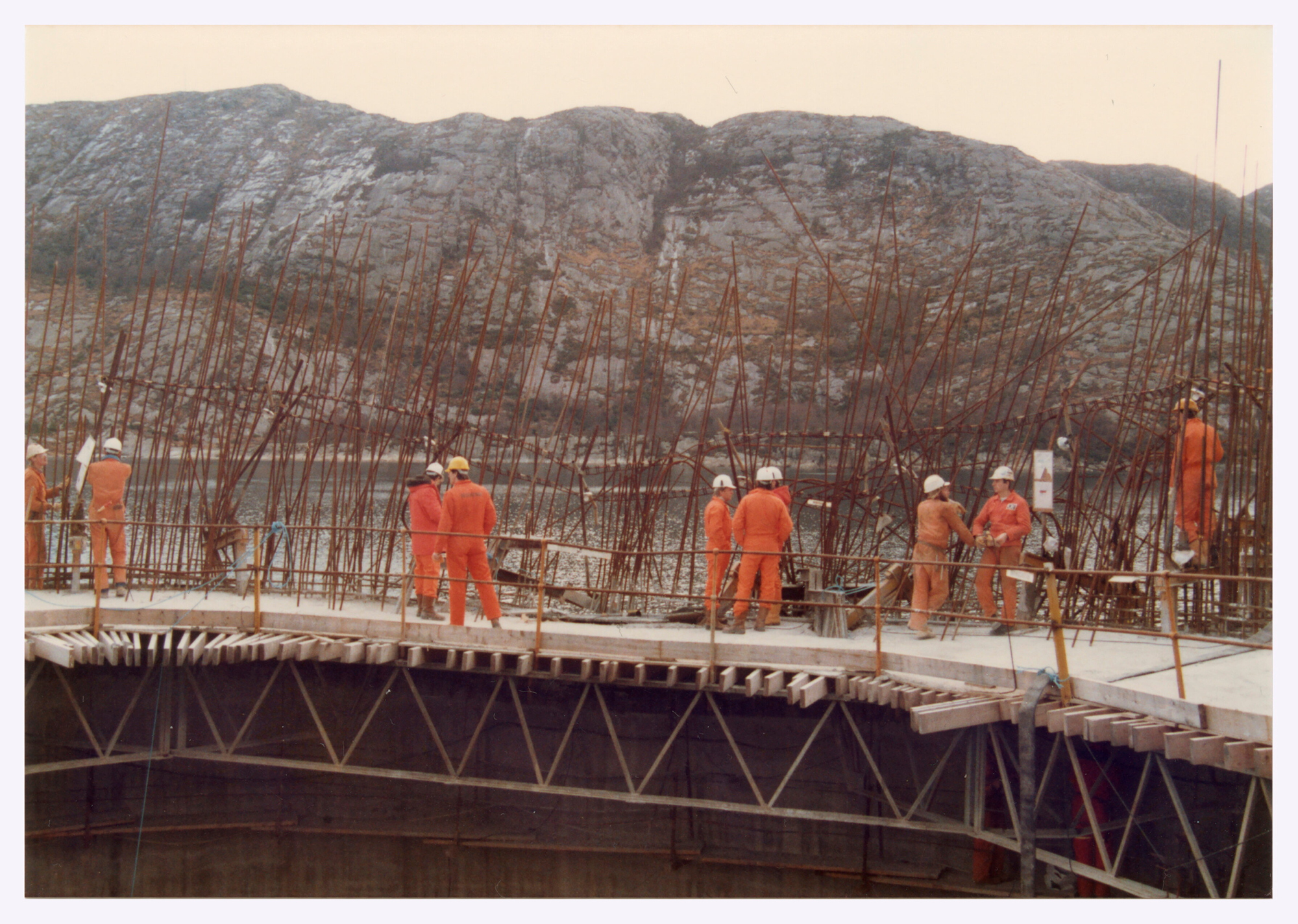

NC justified the reduced rate by pointing to major investments aimed at improving efficiency and easing the workload. A new pump system had been installed to transport concrete up to the slipform platform, where the structure was continuously cast upwards. The crane system had also been improved, reducing the distance workers needed to walk when transporting concrete in wheelbarrows. NC management therefore argued that an increased piecework target was reasonable. The workers, however, believed the workload had actually increased.

This led to a standoff. On October 7, 1985—the day the slipform process for Gullfaks B was supposed to begin—200 permanent employees received layoff notices, while 600 temporary workers were dismissed.[REMOVE]Fotnote: Risholm. T. (08.10.1985) 200 permittert ved Norwegian Contractors. Stavanger Aftenblad s. 7 The move was somewhat paradoxical, as the root cause of the conflict was a labor shortage.

The workers’ representatives argued that the 200 layoffs were unjustified since, at the time the notices were issued, formal negotiations had not yet broken down. They received support from the leadership of the Norwegian Union of General Workers.[REMOVE]Fotnote: Risholm. T. (09.10.1985) Fortsatt strid i Hinnavågen. Stavanger Aftenblad s. 7

The layoffs for permanent employees were set to take effect on October 22 unless an agreement was reached. As for the 600 temporary workers, NC stated they would be rehired once work resumed.

Reaching a Settlement

On October 21, just one day before the layoffs were set to take effect, the parties reached an agreement. The workers secured a 9 percent wage increase per hour compared to the rates paid during the construction of the Gullfaks A substructure.

The conflict had lasted for two weeks—longer than any previous dispute in NC’s history.[REMOVE]Fotnote: Risholm, T., & Uppstad, K. (1985, 17. oktober). Nytt tilbud i NC-konflikten: Klubben uenig i økt glidehastighet uten lønnskompensasjon. Stavanger Aftenblad, s. 9 With the wage issue resolved, work on the foundation cells for Gullfaks B could finally begin. NC estimated that the conflict had cost the company up to NOK 2 million.[REMOVE]Fotnote: Vedvik, N.K. (1985, 22. oktober) 4.50 mer på NC. Stavanger Aftenblad, s. 24

On October 22, NC placed an advertisement on the front page of Stavanger Aftenblad, calling on the dismissed temporary workers to return to work.

📷 Caption: The 600 temporary workers who were dismissed on October 7 were invited to return to work.

📖 Source: Stavanger Aftenblad, October 22, 1985

With that, the next phase of construction was underway. However, it was only a matter of days before work was interrupted again—this time due to one of the most serious accidents in Norwegian oil industry history.

On November 4, 1985, the barge Concem, which supplied concrete to Gullfaks B, capsized. There were 22 people on board. Ten of them lost their lives.