Early Development Plans for Gullfaks

Before the feasibility study, the license had drilled a total of eight appraisal wells in the reservoir, several of which showed promising results.[REMOVE]Fotnote: Statoil ASA (1980), Feasibility Study, Volume I: Summary and Conclusions (Archive reference: AV/SAST-A-101656/0001/D/Dc/L0831/0003). Central Archive/Remote Archive, Case and Correspondence Archive, Corporate Archive. Statoil estimated that the field contained 225 million recoverable tonnes of oil equivalents. Of this, 126 million tonnes were oil, and 14 billion standard cubic meters of gas had already been confirmed. However, there was significant uncertainty regarding the total volume of oil and gas in the field. Saga argued that the uncertainty was so high that Statoil should not have included specific figures in the report.

As of 2025, the actual produced reserves are nearly double what the companies initially believed possible in 1980.

Despite this uncertainty, all three license partners—Statoil, Hydro, and Saga—along with Esso Exploration Norway, which had acted as the technical assistant throughout the process, agreed that developing the field was commercially viable. The field, later named Gullfaks, was deemed economically feasible.

Development Concepts

The method of development, however, was far from set in stone—or concrete. Uncertainty was particularly high regarding the second phase of development, and adjustments would be necessary based on new reservoir data. During the initial assessments, the western part of the reservoir was prioritized, forming the core of the first development phase. The license partners had less knowledge about the eastern part of the reservoir.

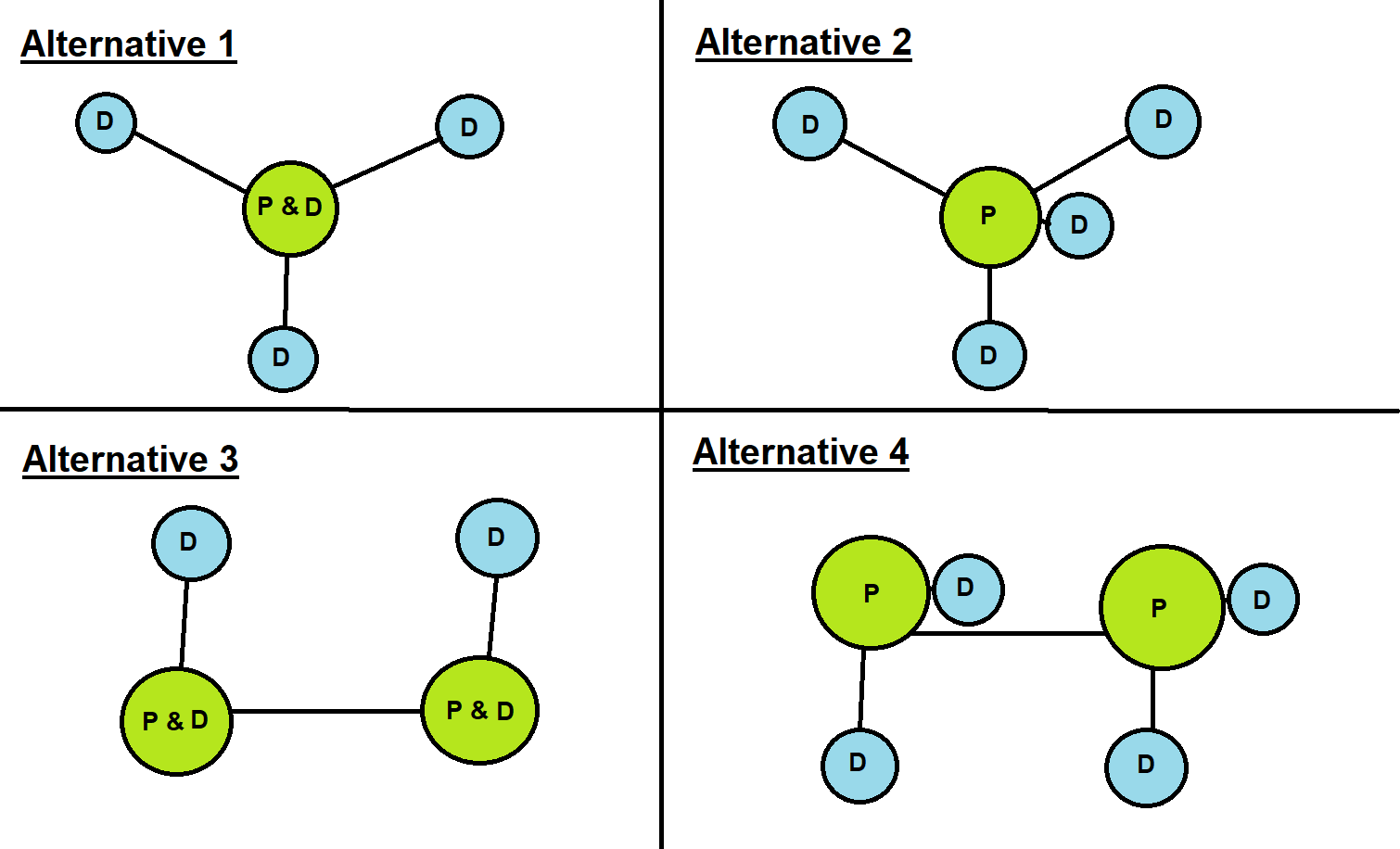

In the feasibility study, Statoil outlined four main development alternatives, each with subcategories and variations:

- One processing platform with a capacity of up to 300,000 barrels per day, plus three drilling platforms.

- One processing platform without drilling functionality, with a capacity of up to 300,000 barrels per day, plus four drilling platforms, one of which would be connected to the processing platform via a bridge.

- Two processing platforms, each with a capacity of 245,000 barrels per day, plus two drilling platforms.

- Two processing platforms without drilling functionality, each with a capacity of 245,000 barrels per day, plus four drilling platforms, two of which would be connected to a processing platform via a bridge.

The figure below visualizes these four alternatives, showing only the types of platforms and their connections—not their exact locations.

All four concepts were designed to be adaptable as more reservoir data became available, particularly for Phase II.

Alternatives 2 and 4 involved constructing processing platforms without drilling functions, with drilling operations conducted from separate platforms, some of which were connected by bridges. Alternatives 1 and 3 integrated all functions on the same platform, supplemented by two to three additional drilling platforms.

Statoil’s Preferred Alternative

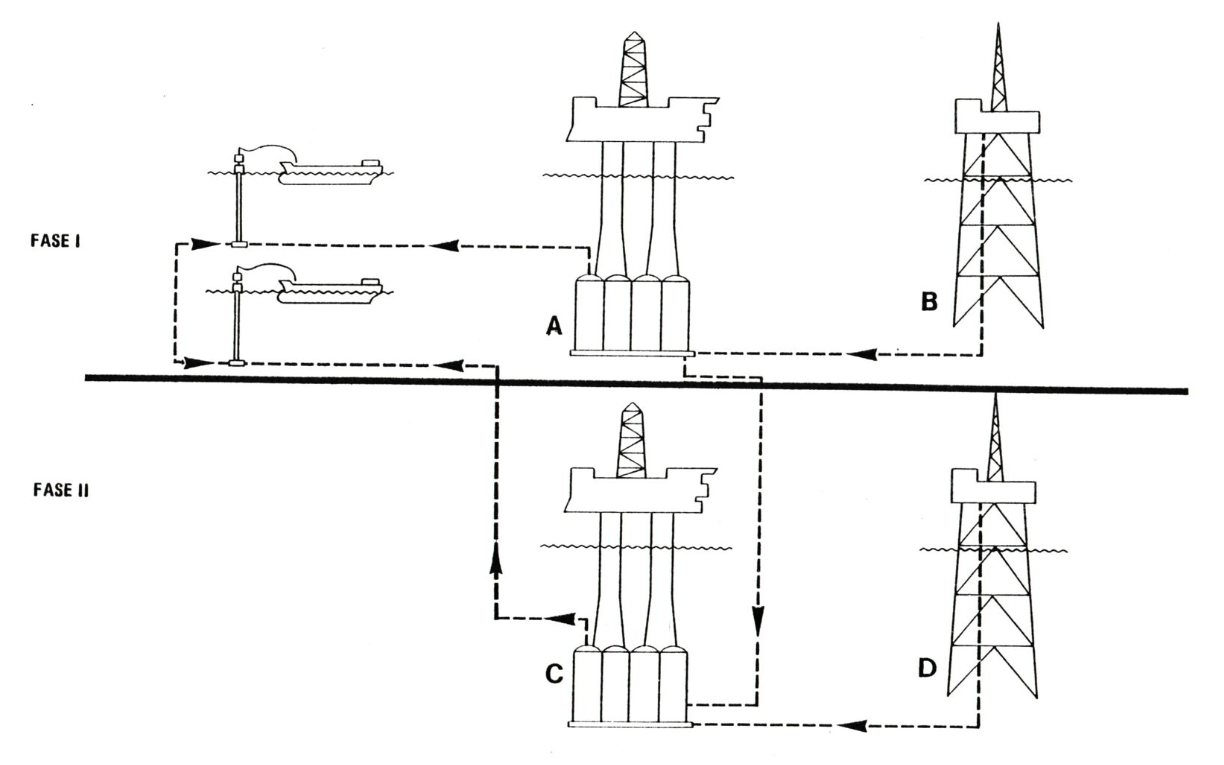

Statoil selected Alternative 3 as the basis for the field development plan. This meant a total of four platforms: two integrated drilling, living quarters, and processing platforms, and two drilling and living quarters platforms.

This alternative proposed a two-phase development: each phase would include the construction of one drilling and processing platform and one drilling platform. The processing platforms would be built in concrete, while the drilling platforms would be steel structures.

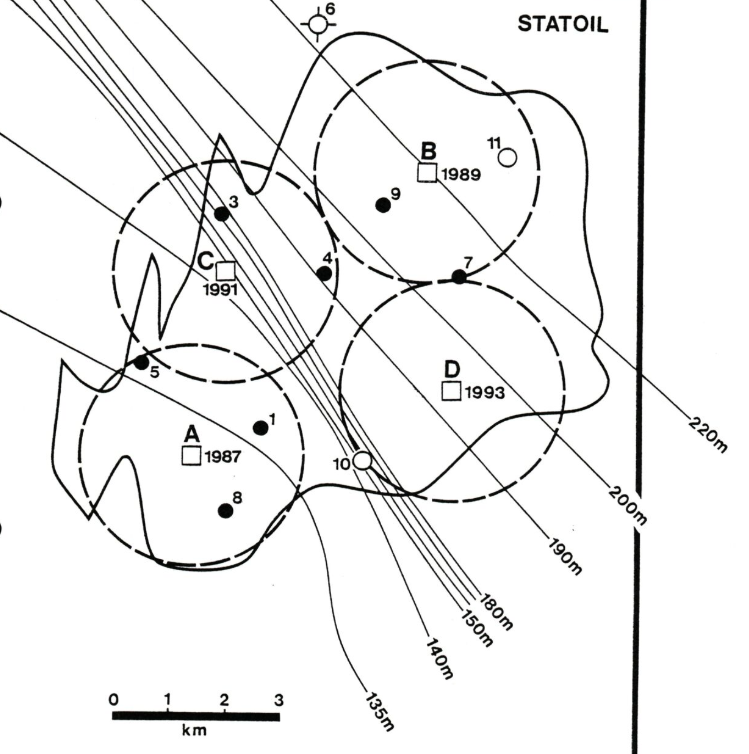

The exact placement of the platforms had not yet been determined. Of the four, Platform A was the most concretely planned and was to be located in the southwestern part of the reservoir. Platform B, scheduled for the same development phase as A, was initially intended for the opposite end of the reservoir.

Disagreements Among License Partners

While Statoil’s two license partners, Saga and Hydro, agreed on the overall feasibility of the development and the two-phase approach, they had different views on key details.

Saga primarily raised concerns about the project’s profitability, arguing that Statoil overestimated the negative impact of the tax system on returns.

Hydro’s objections were more fundamental. The company advocated for Alternative 2 instead of Alternative 3. Hydro proposed building only one processing platform without drilling functionality, supported by multiple separate drilling platforms—one of which would be connected to the processing platform via a bridge.

Choosing this model, with a single processing platform instead of two, would have significant consequences for the field’s development. The license partners had to decide between these alternatives before construction of the first platform began.

With only one processing platform, it would need to be strategically located to efficiently receive oil and gas from all drilling platforms. If two processing platforms were built, the A-platform could be placed less centrally, further west in the field.

In the feasibility study, Hydro emphasized that the placement of the A-platform, which all partners agreed would have processing facilities, had not been finalized. Hydro also stressed that additional well data should be considered before making a final decision. Saga similarly highlighted the importance of incorporating new geological information before committing to a specific development plan.

Alternative 3 with Three Platforms

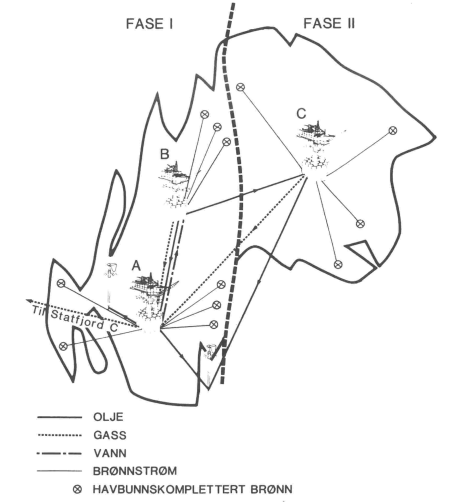

In the end, Statoil prevailed with a modified version of its preferred alternative. Notably, none of the options proposed in the feasibility study fully matched the final development plan. The Gullfaks field was ultimately developed with three platforms:

- Gullfaks A and C: Equipped with drilling, processing, storage, and living quarters.

- Gullfaks B: Equipped with drilling, living quarters, and only first-stage separation.

The figure below illustrates the license’s plan for Phase II, where the C-platform was to be placed in the eastern part of the reservoir.[REMOVE]Fotnote: St.prp.nr.86 1984-85 Utbygging av Gullfaks fase II s.9 https://www.stortinget.no/no/Saker-og-publikasjoner/Stortingsforhandlinger/Lesevisning/?p=1984-85&paid=2&wid=b&psid=DIVL524&pgid=b_0417

This solution was essentially a scaled-down version of Alternative 3, with one fewer drilling platform. The reason for this adjustment was that Well 10, drilled in the southeastern part of the reservoir, was dry. This eliminated the need for a separate platform in that area.[REMOVE]Fotnote: Hatlestad. H, Femti år med oljeproduksjon : min historie (2021). s. 39

Discovering Gullfaks: Hiccups and BlowoutsParliament greenlights Gullfaks, Statpipe, and Kårstø