Disagreement over development plan for Gullfaks C

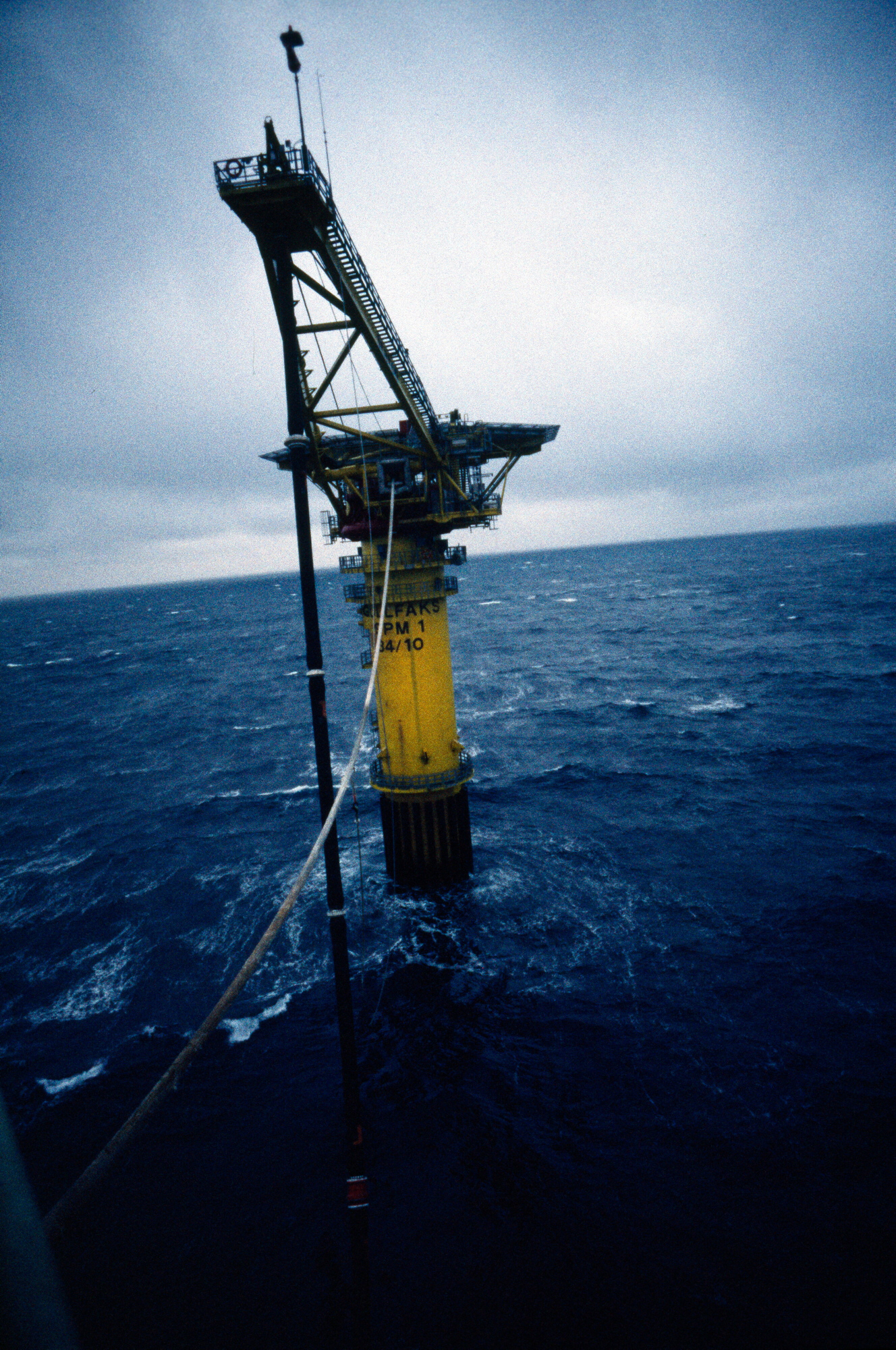

On February 8, 1985, the Gullfaks partners—Statoil, Norsk Hydro, and Saga Petroleum—submitted their recommended development plan for Gullfaks Phase II (Gullfaks C) to the authorities. The plan proposed a fully integrated processing platform, targeting production startup in 1990. The platform would be placed at a depth of 217 meters, marking the first Norwegian continental shelf (NCS) development at over 200 meters depth.

Gullfaks C was to be the heaviest platform ever constructed. Its design closely resembled that of Gullfaks A, which was also a fully integrated production and housing platform, albeit situated in shallower waters (135 meters). Reusing the Gullfaks A design was expected to save NOK 800 million, a figure supported by the Norwegian Petroleum Directorate (NPD).

Saga’s Alternative: A Satellite Solution

The partners’ recommendation was not unanimous. Saga Petroleum preferred a different approach, proposing a simpler satellite platform that would produce partially stabilized oil for processing, storage, and loading at Gullfaks A.

While Saga’s solution would have been simpler to develop, it had a critical drawback: production would not begin until 1996. The satellite platform’s reliance on Gullfaks A’s processing capacity meant waiting for spare capacity, delaying production significantly.

Saga also questioned the geology assessments for the eastern part of the Gullfaks reservoir and disputed the cost savings anticipated from replicating Gullfaks A’s design. However, despite its reservations, Saga was willing to contribute to the project costs and move forward with Statoil and Hydro’s preferred solution.[REMOVE]Fotnote: Alsaker. S. (7.juni 1985) Forhandlinger i Stortinget nr. 314. Utbygging av Gullfaks fase II m.v. Stortinget. S. 4631 https://www.stortinget.no/no/Saker-og-publikasjoner/Stortingsforhandlinger/Lesevisning/?p=1984-85&paid=7&wid=a&psid=DIVL708&pgid=c_1109

Several factors worked against Saga’s position:

- Saga lacked operational experience, which likely diminished the credibility of its proposal compared to Statoil and Hydro.

- The mid-1980s was a challenging period for Norway’s shipyard industry. Statoil’s plan for a faster and more comprehensive development gained broad support from stakeholders in the supply chain.[REMOVE]Fotnote: Ryggvik, H., & Smith-Solbakken, M. (2003). Norsk oljehistorie. Bd. 3: Blod, svette og olje. Ad Notam Gyldendal. s.412

Disagreement Over Oil Transportation

Saga also diverged from the majority regarding oil transportation. It supported reviving plans for a joint pipeline from Gullfaks via Oseberg to the Sture terminal. Statoil and Hydro, however, favored shuttle loading, as was already in use for Gullfaks A and B.[REMOVE]Fotnote: St.prp.nr.86 1984-85 Utbygging av Gullfaks fase II s.11-12 https://www.stortinget.no/no/Saker-og-publikasjoner/Stortingsforhandlinger/Lesevisning/?p=1984-85&paid=2&wid=b&psid=DIVL524&pgid=b_0417

This pipeline idea had been proposed a year earlier in 1984, with Statoil initially as its proponent. At that time, Statoil sought to direct Gullfaks and Oseberg oil to its Mongstad refinery. However, by 1985, it had been decided that Oseberg’s pipeline would connect to Sture, and Statoil aligned with Hydro to prioritize shuttle loading for Gullfaks C.

There was little difference in the investment estimates for the two transport solutions. Saga estimated that both shuttle loading and pipeline transport would cost approximately NOK 1.08 billion. Statoil calculated a marginal NOK 15 million advantage for shuttle loading, while Hydro argued that pipeline transport would be significantly more expensive, at NOK 1.3 billion.

The Ministry of Petroleum and Energy noted that a pipeline connection to Oseberg would require expansion, a cost naturally falling to the Gullfaks license group.[REMOVE]Fotnote: St.prp.nr.86 1984-85 Utbygging av Gullfaks fase II s.12 https://www.stortinget.no/no/Saker-og-publikasjoner/Stortingsforhandlinger/Lesevisning/?p=1984-85&paid=2&wid=b&psid=DIVL524&pgid=b_0417 Additionally, a pipeline would reduce the design similarities between Gullfaks C and A, undermining the expected cost savings from replication.

Concerns About Loading Buoys from Statfjord

One significant concern raised doubts about shuttle loading as the optimal solution for Gullfaks C. After just six years in operation, the loading buoy for Statfjord A was too worn to continue service and had to be towed to land. The Statfjord consortium assumed it was unlikely to be reusable.

Svein Alsaker, parliamentary rapporteur for Gullfaks Phase II, highlighted the disturbing reports about the lifespan of loading buoys in the parliamentary debate.[REMOVE]Fotnote: Alsaker. S. (7.juni 1985) Forhandlinger i Stortinget nr. 314. Utbygging av Gullfaks fase II m.v. Stortinget. S. 4632 https://www.stortinget.no/no/Saker-og-publikasjoner/Stortingsforhandlinger/Lesevisning/?p=1984-85&paid=7&wid=a&psid=DIVL708&pgid=c_1109

The Norwegian Petroleum Directorate (NPD) had initially estimated the lifespan of a loading buoy to be around 30 years. However, the wear and tear on the Statfjord A buoy led the NPD to revise this estimate down to 5 to 15 years.

The reduced durability of loading buoys made pipeline transport appear more attractive for future projects. The successful crossing of the Norwegian Trench by the Statpipe gas pipeline further supported the case for pipelines over shuttle loading.

Despite these concerns, the Gullfaks consortium reassured authorities that the loading buoys for Gullfaks would be more robust than those used at Statfjord A. Their claims proved accurate: Gullfaks’ buoys remained operational for 30 years before being replaced.

In the end, Parliament approved Statoil and Hydro’s proposal. All three Gullfaks platforms would export oil to tankers via shuttle loading, while gas would be transported by pipeline. Like the A-platform, Gullfaks C would be an integrated drilling, processing, and accommodation platform with a concrete gravity base structure.