Building Hywind Tampen

Plans for Hywind Tampen were first announced by Statoil at the ONS oil and energy exhibition in 2018. A few months later, in March 2019, the environmental impact assessment was submitted to the Ministry of Petroleum and Energy.

Project description

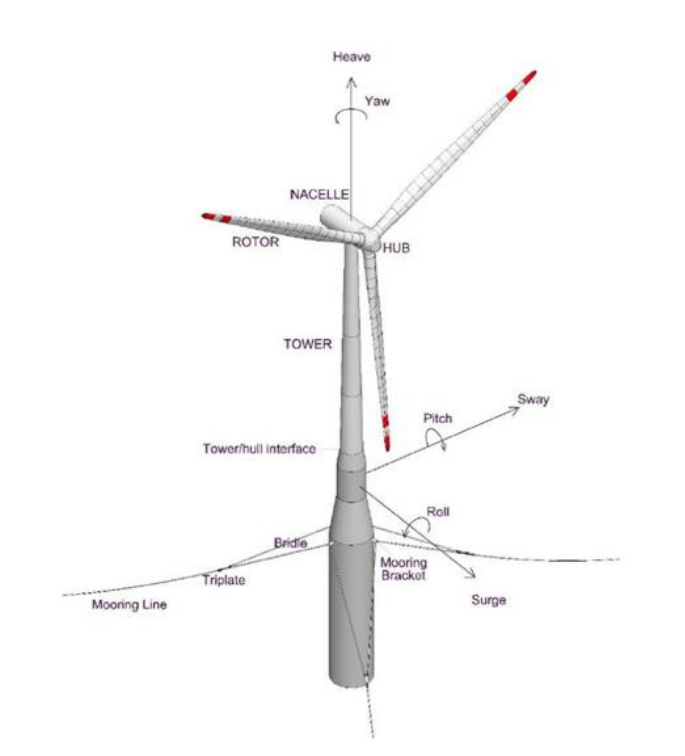

Hywind Tampen comprises 11 floating wind turbines installed at sea depths ranging from 260 to 300 metres. Positioned between the Snorre and Gullfaks fields, they provide renewable power to the offshore platforms, supplementing the gas turbines used on site.

Each turbine stands 190 metres above the sea surface and rests on a submerged concrete substructure extending 90 metres downward. The rotor blades have a diameter of 167 metres.

Equinor conducted design studies for substructures in both steel and concrete. The environmental impact assessment concluded that concrete was the preferred material—using the same design model as the Hywind Scotland turbines that had been deployed off the coast of Scotland a few years earlier. The decision was based on the fact that this concept had already been tested and was considered technically mature enough for use at Tampen.

Each turbine generates 8 MW. Six of them supply power to Snorre A, while five are connected to Gullfaks A. The turbines are linked through a circular grid system, which allows energy to be redistributed from Gullfaks to Snorre. This design enables flexibility as future power demand at Gullfaks is expected to decrease along with declining production.[REMOVE]

Fotnote: Equinor. (2019, mars). Hywind Tampen PL050 – PL057 – PL089 PUD del II – Konsekvensutredning (s. 30).

Construction

Construction of the various components took place at multiple locations across Norway and Europe.

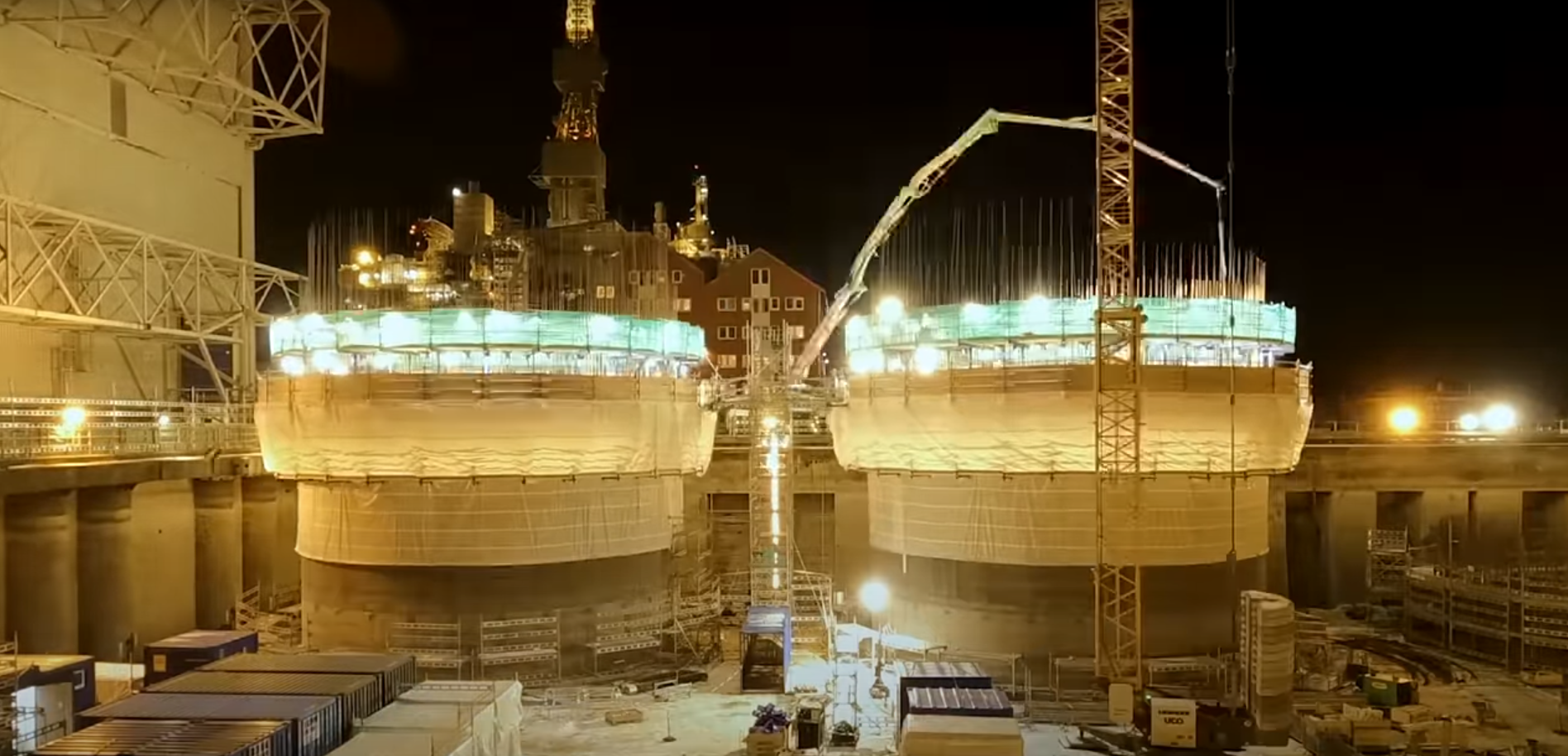

The concrete foundations were built by Aker Solutions. The first 20 metres of each foundation were cast at Stord.

The structures were then towed to Dommersnes in Vindafjord, where casting continued vertically.

The method used in this stage of the construction process is known from the Condeep era as “slipforming.” As the concrete structure grows taller, it is gradually lowered into the fjord. The construction technology for the substructures is based on the same principles used in building Condeeps. In total, about 32,000 cubic metres of concrete were used across all 11 platforms.

This may seem like a vast amount of concrete, but it still represents only 13 percent of the volume used in the construction of the Troll A platform.[REMOVE]

Fotnote: Det ble brukt 245 000 kubikkmeter betong i Troll A.

Heidelberg Materials. (n.d.). Troll A. Hentet 9. oktober 2024 fra https://sement.heidelbergmaterials.no/no/Troll_A

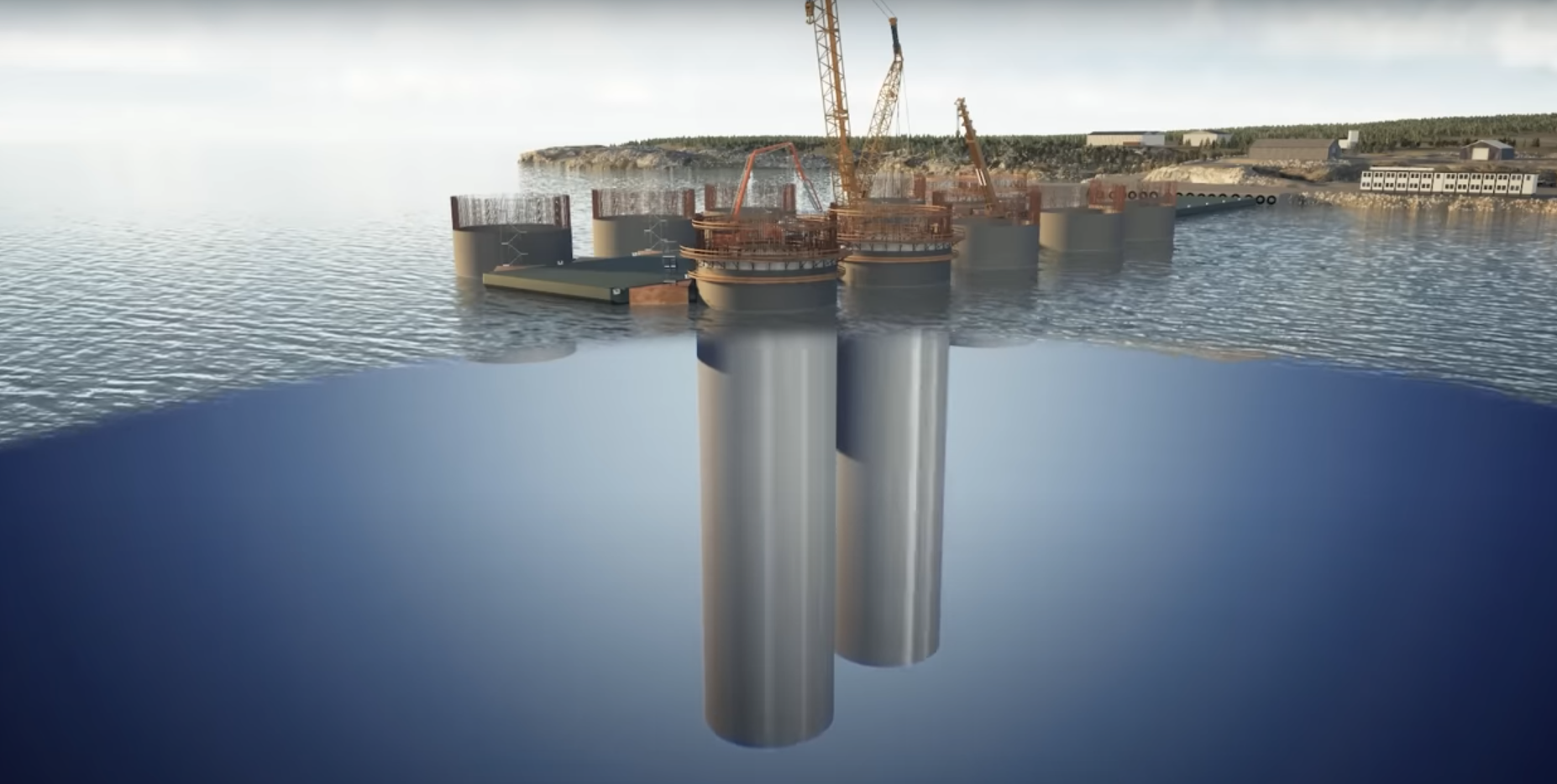

The concrete element was then transported—along with other turbine components—to the Gulen industrial port in Sløvåg, where the assembly took place.

During this phase, the underwater structures were first moored to the quay.

Next, the towers were installed. Each tower was assembled from four segments stacked on top of each other. Then, the nacelle—which holds the rotor hub—and the three rotor blades were lifted into place using a land-based crane.

Towing and installation

Once the internal equipment had been installed, the turbines were towed to the field. The first turbine was ready for towing in June 2022. One by one, the turbines were moved to the field, 140 kilometres offshore.

Each turbine was anchored to the seabed using a total of 19 suction anchors and corresponding chains. These anchoring systems had already been pre-installed on the seafloor ahead of the turbines’ arrival.

The anchors are designed to be retrievable using remotely operated vehicles (ROVs) when the facility is eventually decommissioned.[REMOVE]

Fotnote: Equinor. (2019, mars). Hywind Tampen PL050 – PL057 – PL089 PUD del II – Konsekvensutredning (s. 32).

The first seven turbines were towed out during the summer of 2022. The remaining four followed in the summer of 2023. By the end of the summer, all 11 turbines were up and running.

In this video produced by Equinor, you can follow the step-by-step construction of Hywind Tampen.

Should the Condeep Giants Join UNESCO’s World Heritage List?The Age of Drones